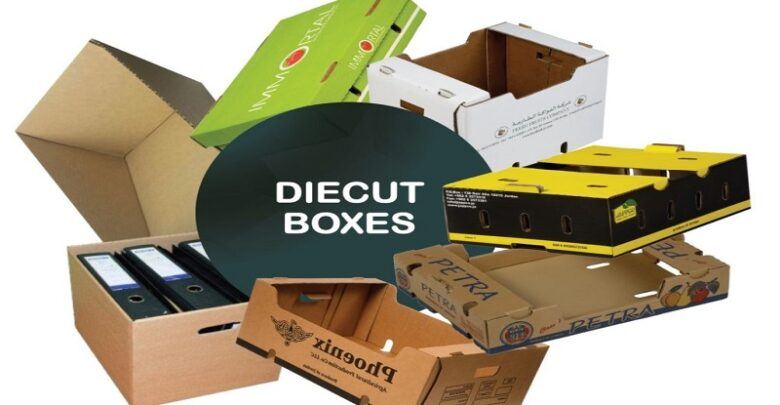

There are all sorts of items as we reach every shop and too many brands to look at one glance, all these products are packaged in boxes, these boxes are known as die-cut boxes. In a supermarket, customers are often drawn to the most wonderfully packaged package that is attractively crafted in a die-cut box. Thanks to technology and research, we can produce and manufacture virtually all sorts of die-cut boxes to attract the target market/consumer in diverse styles and shapes. In all types of styles, these die-cut boxes are available such as printed die-cut packaging that make your brand illuminated in the shop loaded with various types of die-cut boxes.

The cut boxes are made of cardboard of high quality. They even display your parts in the interior of the case. They are decorative. These are rigid boxes and because of these specifications, the form of each box varies. The cutting tools are used to give these boxes a special appearance and a distinctive appearance. These machines will create custom die-cut boxes with new cuts and designs. The 4 walls of such boxes are fixed to a foundation. The side flaps are adjustable and lockable on all their opposite walls. Adjusting the tabs together gives them a structure that can accommodate objects. Each of these flaps has a top layer covering the box completely and providing protection for the object inside. There are different means of securing the box through various kinds of locks. These boxes often have window cuts to improve their appeal and boost quality.

Protectiveness:

Die-cut boxes have the ability to stay rigid and keep the goods cushioned reducing the risk of loss of delicate items. These boxes are specially engineered in a way that they resist impact or vibration damage while shipping. These Die Cut Boxes have a consistent weight to keep the products from moving as much as possible.

Expense Efficient:

The key benefit of die-cut boxes is their cost-efficiency. These cheap die-cut boxes have extremely little raw material and labor. You can conveniently load and move the goods in the cabinets. As more goods can be packed into a die-cut case, you can ship more things at a lower cost without having to rip or damage a package. The boxes can also be repeatedly reused and recycled, they are made of recycled material almost entirely.

The material used for the manufacturing:

Diverse materials as well as diverse styles are used for the manufacturing of die-cut boxes. Materials used for the manufacturing of die-cut boxes have varying properties depending on the type of cardboard used for the item. The basic characteristics needed for the packaging material are toughness, durability, and robustness. Corrugated die-cut boxes, like die-cut boxes Sydney and die cut boxes Melbourne are ideal for such merchandise. These boxes are manufactured to protect the products inside from rupture, injury, or loss, and due to the layers of the packaging material of the box, it is capable of holding objects which are heavy and safeguarding the delicate objects.

First impression:

If you wish to give a spectacular presentation to your product, die-cut boxes are the best option for you. Flat plain boxes are too boring for the customers, they prefer products which are packed in an eye-catchy packaging. Die-cut boxes Australia has a fresh look and it enhances the aesthetic appeal of the items. Numerous die-cut options are depending on the product you wish to pack.

Types of die-cut boxes:

There are several kinds of die-cut boxes ruling the market right now. Custom die-cut boxes have successfully been extremely attention-seeking. Here are some examples of the types of die-cut boxes:

Mailer boxes are now a day one among the top sellers. They are one-piece boxes, and the top deck is formed in a way to open and close the lid. They are very much requested and welcomed by the consumers for packaging in supermarkets also. Many of the boxes are used for the supply of the online ordered items. Custom inserts are often induced to place more than one product properly in these die-cut boxes.

Suit case boxes are the easiest way to get individual die-cut boxes is to customize them in case format or personalized die-cut boxes. It is a box with a handle and an auto-closing feature. Such packaging is ideal for trade shows and conferences. This style gives the product a modern twist. This type of box is often used to make it look appealing for items such as child’s toys.

Vote boxes are chosen for lucky draws, recommendations, etc. They are seen primarily in supermarkets, department stores, and malls. on top of the boxes, visitors can submit contest entries and suggestions with a drop-down slot. Those cases are very helpful for promotion. They also have a collection of their own, for example, a gift box also.

Company logo on the box:

The packaging of a product should also include the logo of the brand as it plays a major role in the company’s identification. For the consumer, the packaging graphics are incredibly relevant also. Cosmetics businesses strive not only to sell a brand to consumers but also an appearance related to certain qualities or features. A successful logo will allow customers to recognize memories and feelings at a glance also.

Bakery Fascination:

Bakeries are known for their taste and style, creativity, and uniqueness. They constantly carry out design tests and try to come up with unique ideas to attract their customers. They use these die cut boxes for items such as donuts, cupcakes, cakes, etc. Besides, the boxes induce special die-cut inserts also. Wholesale die-cut boxes are the option for such kind of business also.

Packaging of gift:

Wrapping the gift is the most essential to boost the beauty, look, and worth of a present. These customize die-cut boxes are suitable as gift boxes. You can also pack gifts for your guests in die-cut boxes such as chocolates or sweets as a sweet gesture. These die-cut boxes will leave a heavy and immaculate impact on them also.